MIRTEC MV-9UP LED Inline 3D AOI High-Precision Automated Optical Inspection for SMT & PCB Assembly

Product Details:

MIRTEC MV-9UP LED Inline 3D AOI High-Precision Automated Optical Inspection for SMT & PCB Assembly Price And Quantity

- 6.0 USD ($)/Unit

- 1 Unit

MIRTEC MV-9UP LED Inline 3D AOI High-Precision Automated Optical Inspection for SMT & PCB Assembly Trade Information

- Cash in Advance (CID)

- 20

- 30

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

Product Description

Prices are for show only, please contact us for exact price.

Product Description

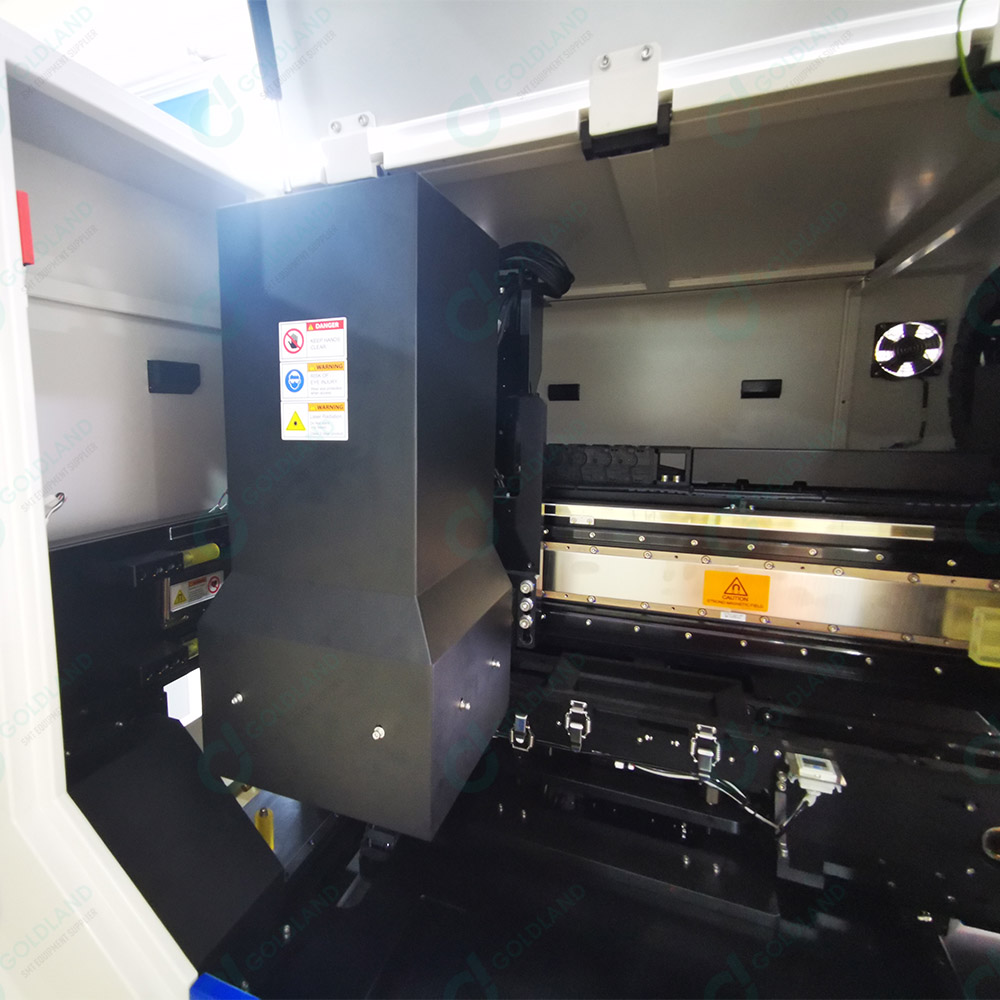

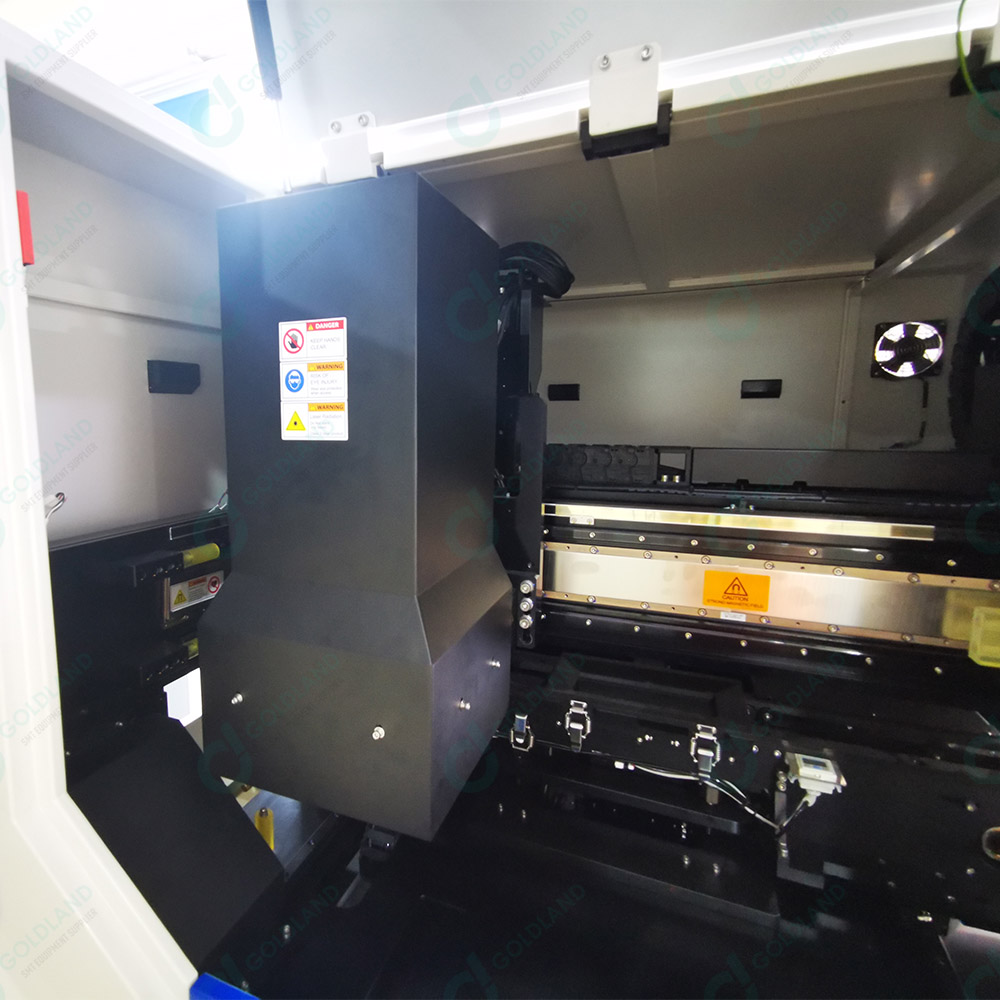

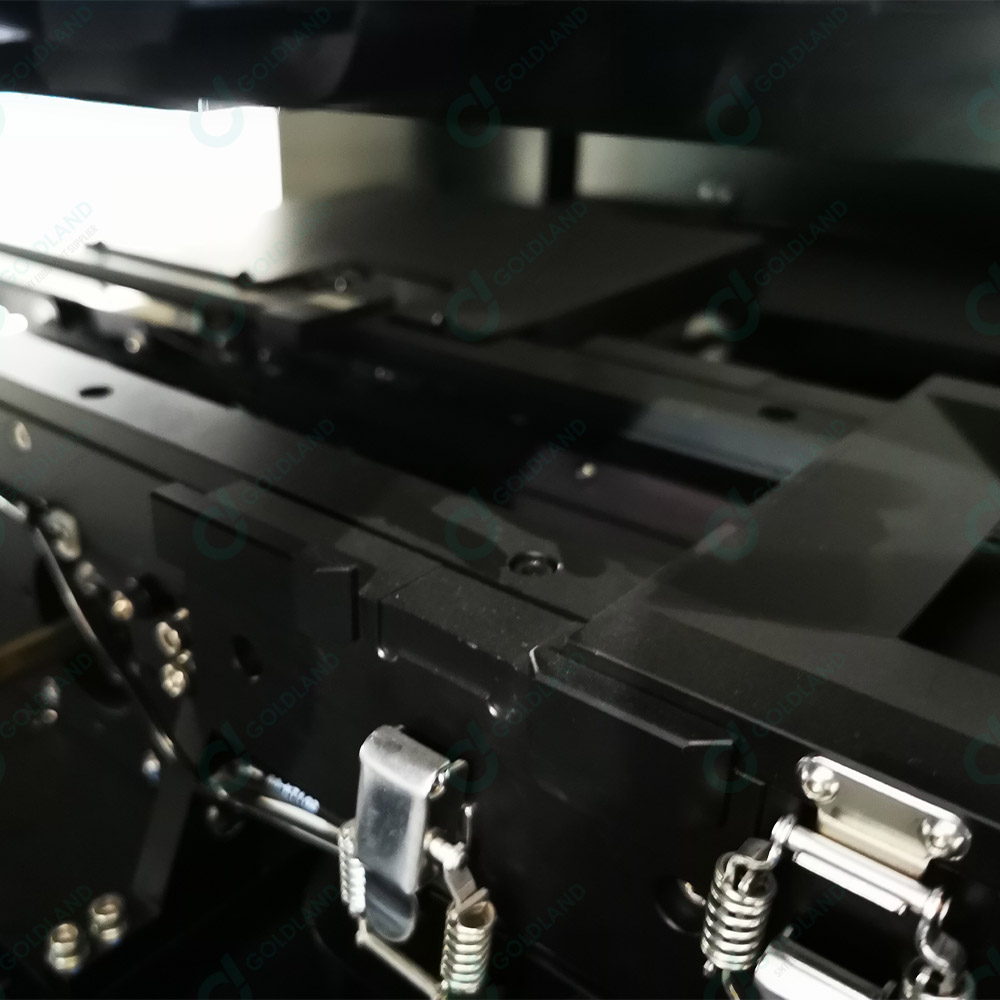

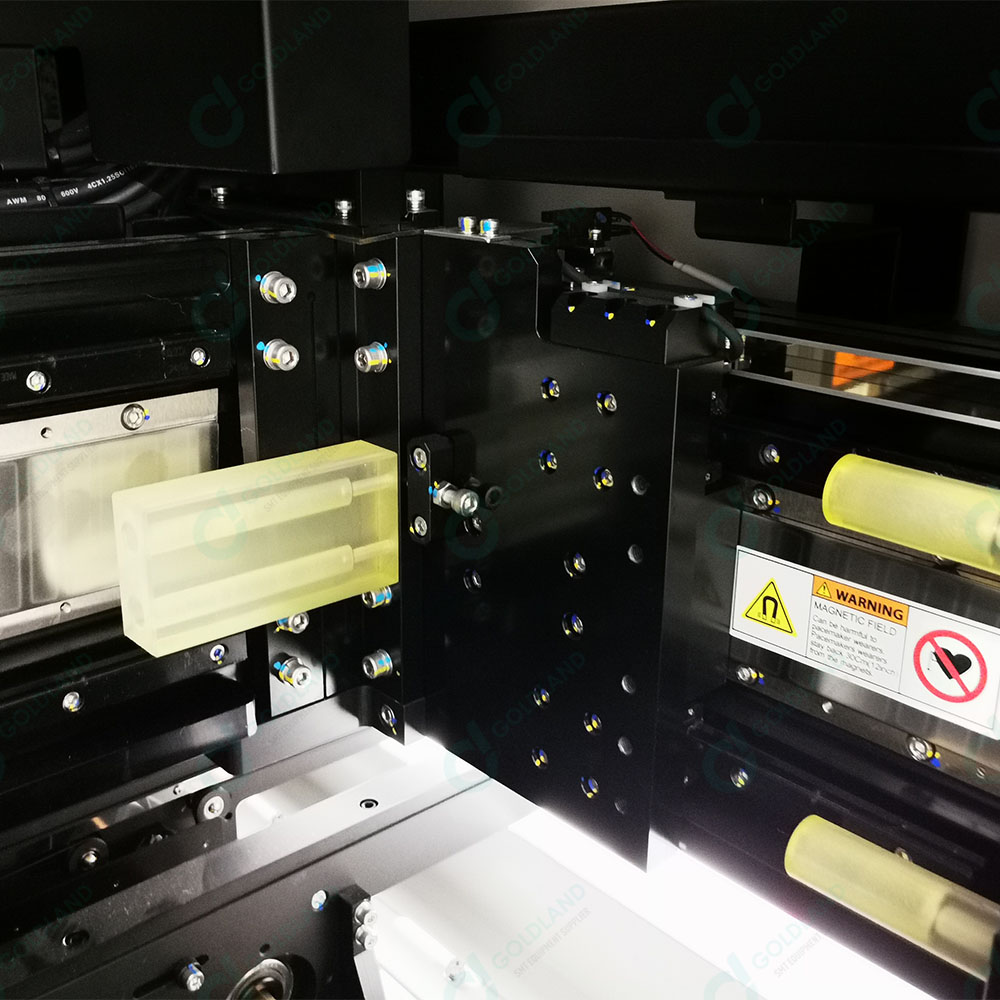

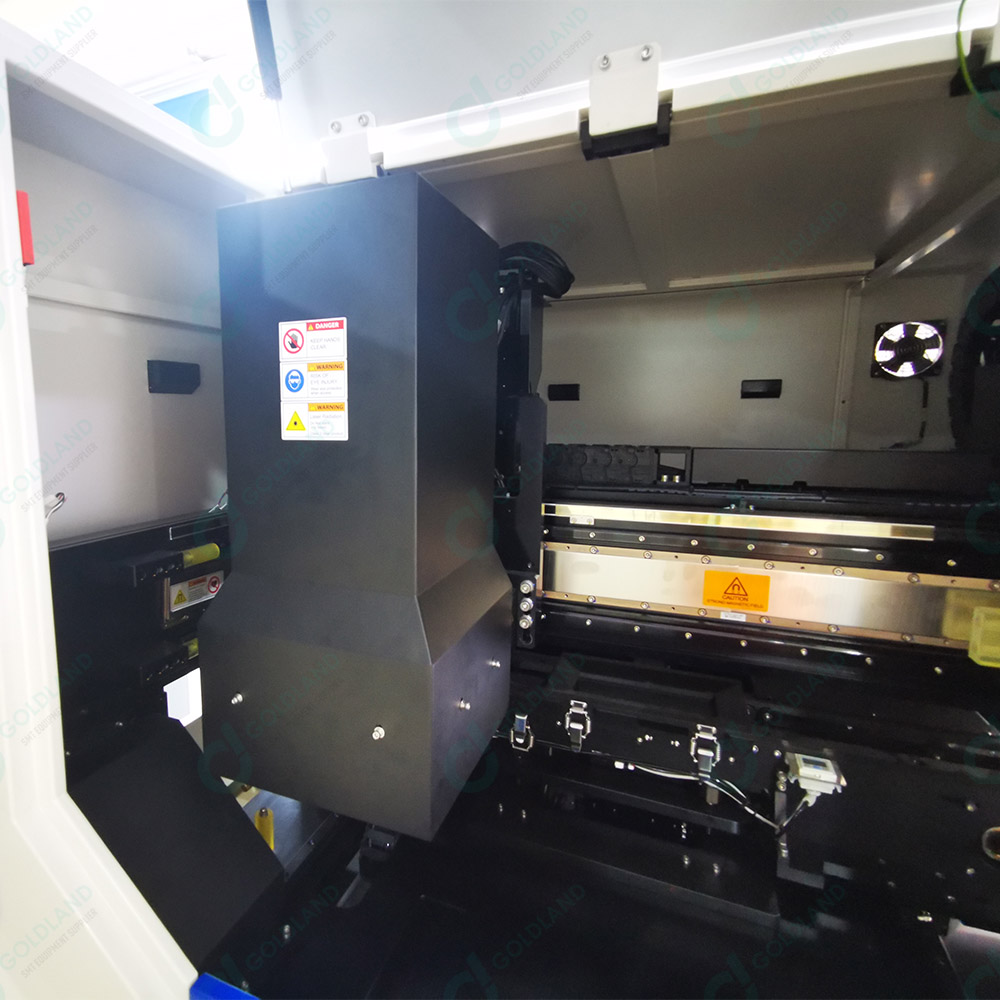

The MIRTEC MV-9UP LED Inline 3D AOI is an advanced Automated Optical Inspection (AOI) system designed for high-precision PCB assembly and Surface Mount Technology (SMT) production. Featuring 3D inspection technology, this inline AOI machine ensures accurate defect detection, covering LED placement, solder joints, component alignment, and polarity. Equipped with high-resolution cameras and an advanced vision system, the MV-9UP provides real-time monitoring and automated defect analysis, reducing false calls and improving production efficiency. The system supports high-speed inline inspection, making it ideal for LED manufacturing, automotive electronics, telecommunications, and consumer electronics. Its intelligent software, multi-angle inspection, and user-friendly interface enable seamless integration into smart factory environments. Enhance your SMT quality control process with the MIRTEC MV-9UP, ensuring high-accuracy, zero-defect PCB assembly for high-volume production lines

Product Specifications

| Model | MV-7XP | MV-9UP | |

| Technology | 2D Inspection | 15 Mega Picel Camera | |

| 3D Inspection | NA | Confocal Sensor | |

| Camera | Camera Spec | 15 Mega Pixel Color Cam era | |

| Resolution | 3,904 x 3,904 (Pixel) | ||

| FOV | 23.42 23.42(mm) | ||

| Confocal Sensor | Resolution | NA | 0.1m |

| Sam pling Speed | Max 22KHz | ||

| Measuring Range | 2, 500m | ||

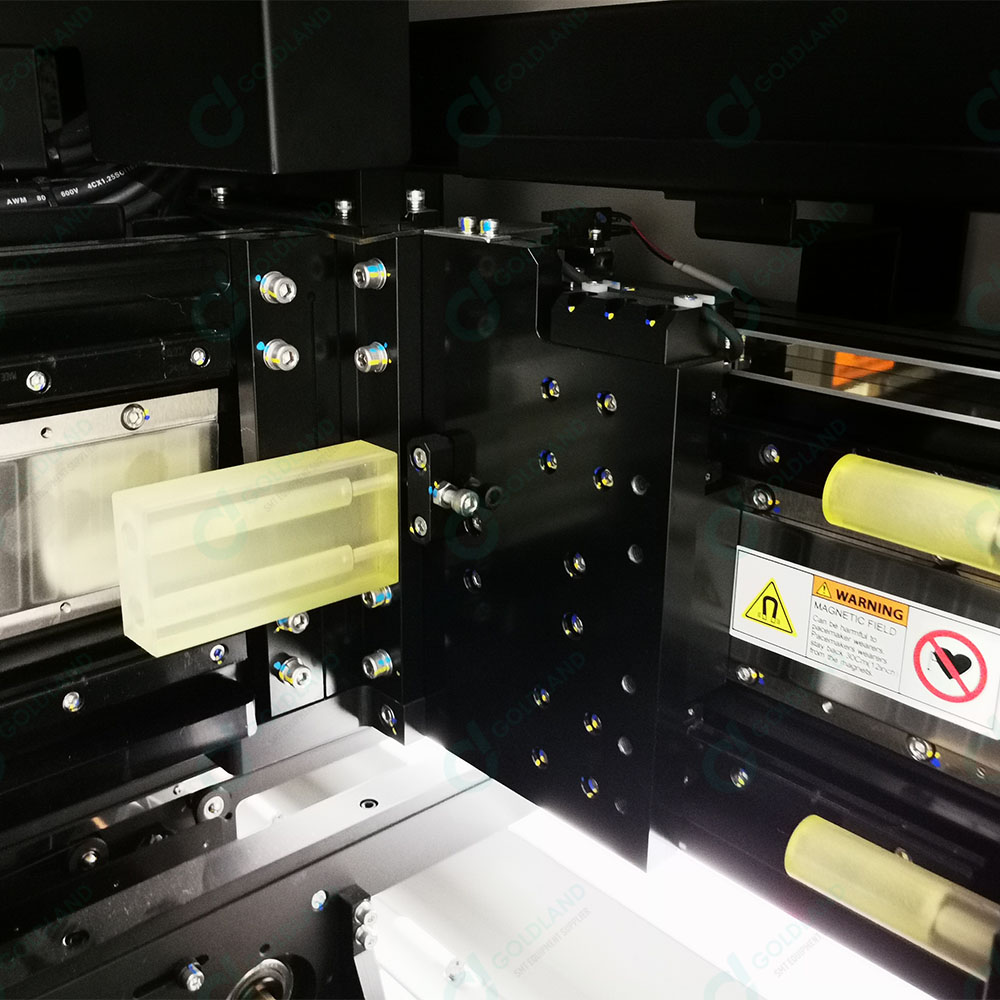

| Lighting Systrm | High brightness Blue Light, Green Light, White Light, Molet Light LED (Able to control each light 255 level) | ||

| Type of Defect | Package : No Package, Broken / Burr, Foreign m aterial - Chip : No Chip, Ink Chip, Model Mixing, Flip, Offset, Rotation, Broken Epoxy, Crack, Scratch, Foreign m aterial - Ball : No Ball, Offset Diam eter -Wire : No Wire, Open, Wrong Tail Double, Bent, Broken, Short, Foreign | Dispensing : Overflow, Underflow - Package : Tilt Broken / Bur, Forngn Metrial, Mask, Scratch - Dispensing : Bubble, Foreign m aterial, Scratch |

|

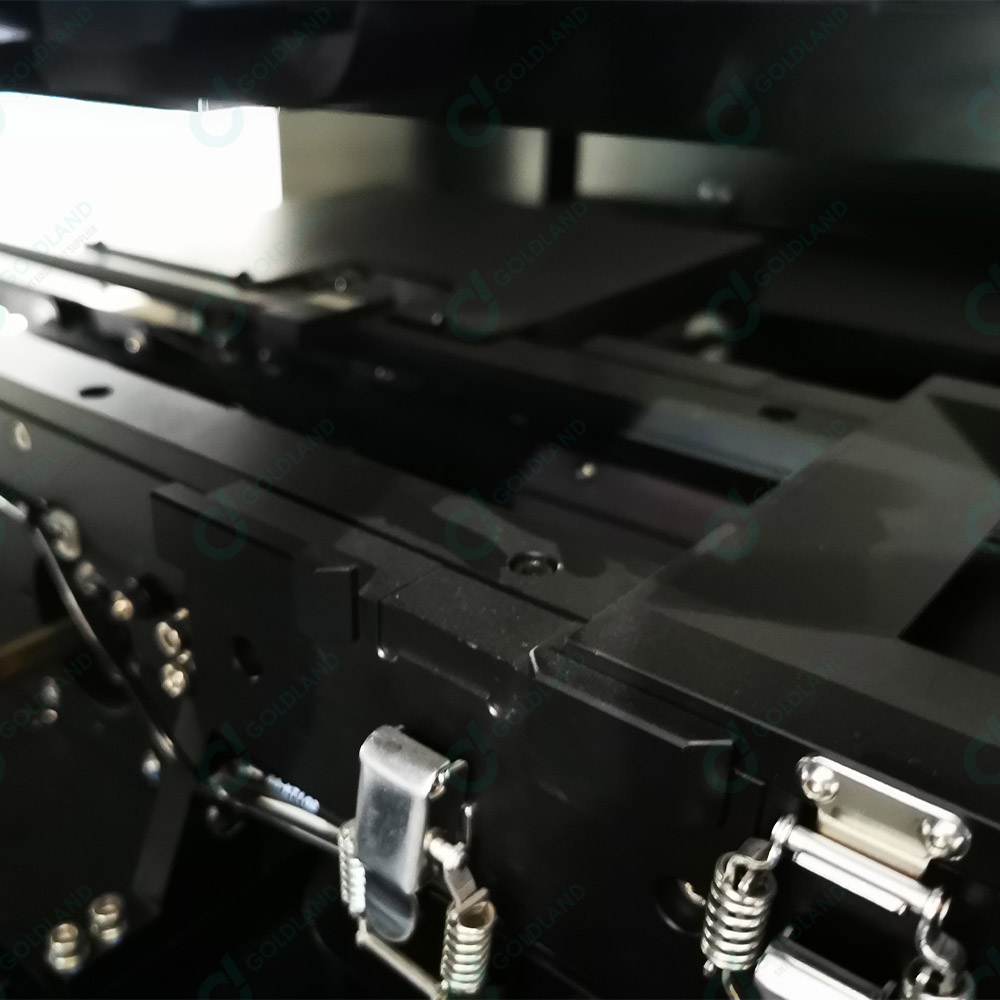

| Robot(X/Y Axis) | 2 Axis Servo Motor System (X-Axds. Y-AxS) | Precision Linear Drive Motor System | |

| Power Requirem ents | Single Phase(s) 200-240V 50~60Hz, 1.1 KW | ||

| Air Requirem ents | 5 Kgf / ar (0.5 Mpa) | ||

| Software | Windows | Windows 7 /64 bit | |

| Machine | Size | 1,100(W) 1,500(D) 1,500(H) | 1,250(W) 1,500(D)1,600(H) |

| Weight | Approx. 1,000 Kg | Approx. 1,200 Kg | |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Solder Paste Inspection & Automated Optical Inspection Machine' category

|

GoldLand Electronic Technology Co., Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |